Overheating is normal and the

most common problem, depending

on the application, can cause

a dangerous deformation of an

otherwise high quality operating

system. This deformation can also

cause a misalignment between

the rod and sleeve, generating

excessive friction during injection.

Premature sleeve erosion and

plunger seizure are the resulting

consequences.

Operating temperatures are

ordinarily high, so it is important to

maintain the target in a safe and

controlled limit.

Overheating is normal and the

most common problem, depending

on the application, can cause

a dangerous deformation of an

otherwise high quality operating

system. This deformation can also

cause a misalignment between

the rod and sleeve, generating

excessive friction during injection.

Premature sleeve erosion and

plunger seizure are the resulting

consequences.

Operating temperatures are

ordinarily high, so it is important to

maintain the target in a safe and

controlled limit.

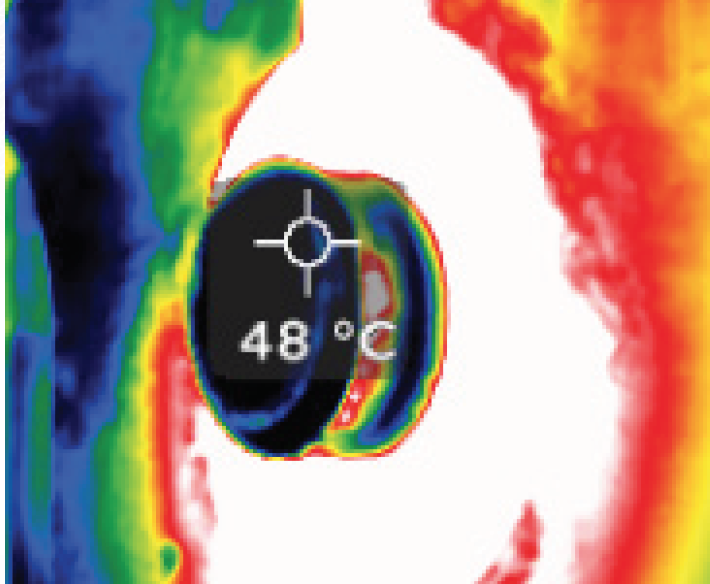

Excessive heating of the shot sleeve, during the injection

process, can be easily identified, measured and located

by using a thermal camera. In the overheated area, the

steel is severely stressed and starts losing its mechanical

properties, especially under the pour hole. When the steel

under the nitrided layer is compromised, the normal result

is premature erosion of the shot sleeve.

Excessive heating of the shot sleeve, during the injection

process, can be easily identified, measured and located

by using a thermal camera. In the overheated area, the

steel is severely stressed and starts losing its mechanical

properties, especially under the pour hole. When the steel

under the nitrided layer is compromised, the normal result

is premature erosion of the shot sleeve.

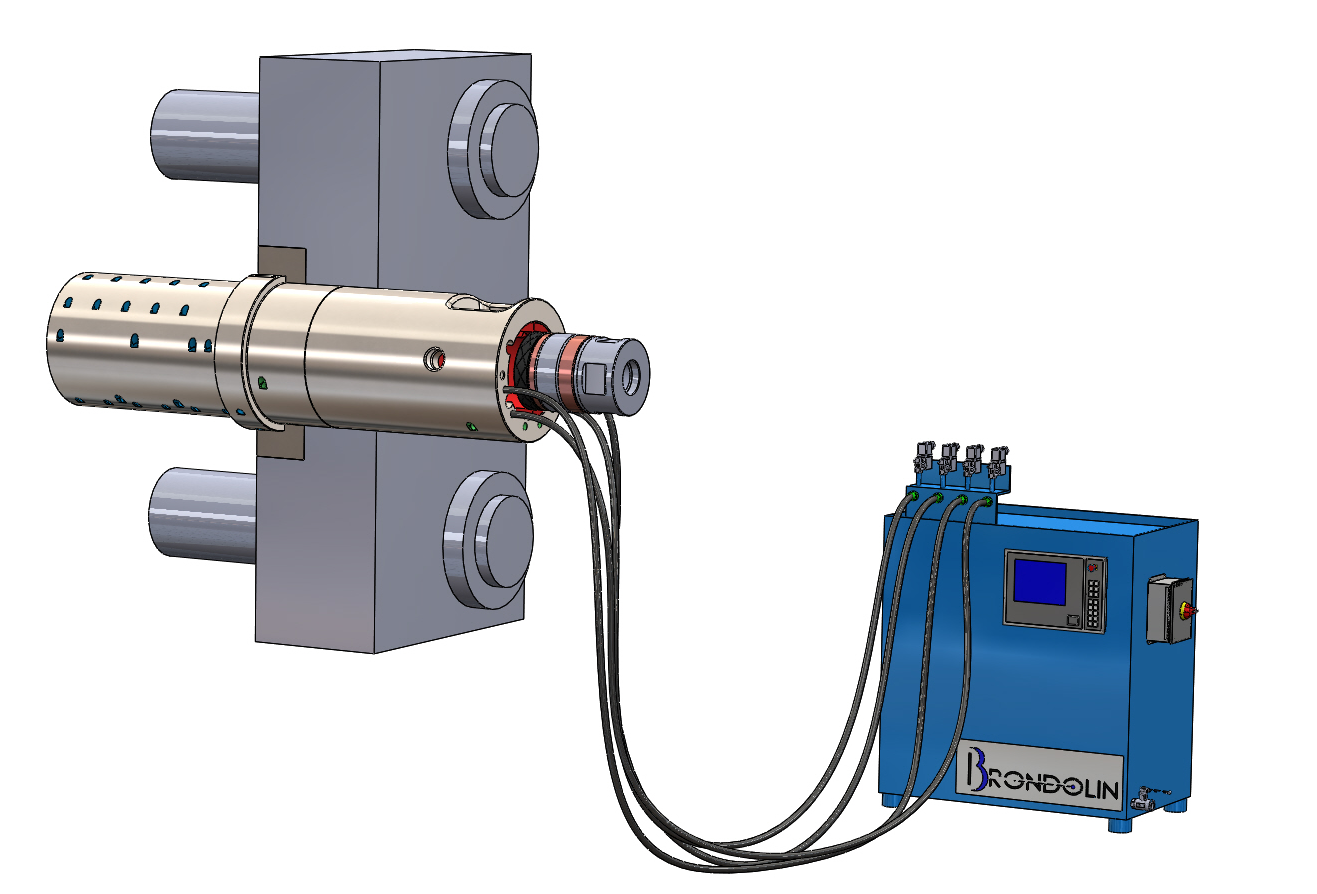

Maintaining a balanced and controlled

temperature is essential not only for the shot

sleeve, but also significantly helps the plunger

system function correctly. A round sleeve has

lower friction, requires less lubricant, has less

metal turbulence, all adding to the ability to

properly thermally regulate the shot sleeve. The

die side of the shot sleeve is heavily thermally

stressed from the heat coming from the biscuit

and is the most critical area of the thermal

circuit layout design. For large shot sleeves, it

is best to also have an independent circuit on

the die side for proper thermal control.

Maintaining a balanced and controlled

temperature is essential not only for the shot

sleeve, but also significantly helps the plunger

system function correctly. A round sleeve has

lower friction, requires less lubricant, has less

metal turbulence, all adding to the ability to

properly thermally regulate the shot sleeve. The

die side of the shot sleeve is heavily thermally

stressed from the heat coming from the biscuit

and is the most critical area of the thermal

circuit layout design. For large shot sleeves, it

is best to also have an independent circuit on

the die side for proper thermal control.